Branden Coker joined the team recently to help develop our animation models into physical figurines. It’s a very labor-intensive process, but the photos below speak for themselves. We asked Branden to go into detail about his process and his art.

On getting into rapid prototyping

I think 3D printing is a common interest among digital artists today. Creating a tangible object from your digital art to have in your hand or on your desk is very appealing. I’m a 3D modeler by profession, and I loved building scale models when I was younger. Those two interests naturally complement each other well.

On the challenges of the Scarab figurine

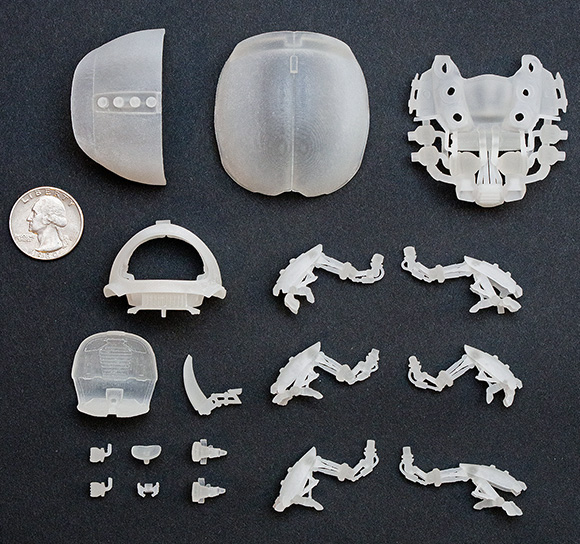

When I set out to create the Scarab print, we were starting with a production model that was created with animation in mind. This is about as far as you can get from a model that’s suitable for 3D printing. The Scarab in its original form was over 900 discrete meshes (or shells). In order to print properly, all of them had to be combined into a single water-tight mesh. The next things to consider were thin walls and other details that the printer wouldn’t be able to reproduce. Those had to be either thickened and enlarged, or eliminated entirely. Finally, to facilitate painting of the final printed model, we decided to break up the mesh into 18 interlocking elements to be assembled after printing. This last step was by far the most challenging part of the project. Assembling all of those parts after the first test print and seeing that they all fit was a great relief!

On the tools of the trade

ZBrush is probably the most often used tool in my toolbox for this kind of work. Without Dynamesh, I probably wouldn’t even attempt a job like this. Another great tool is MeshFusion for Modo. I had some difficult, precise cuts to do on the head of the Scarab that were a little too delicate for Dynamesh. MeshFusion made quick work of it, and the results were better than I could have hoped.

On the future of 3D printing

I think a lot of people who are only moderately familiar with 3D printing may perceive it as having a very narrow purpose. For most people, 3D printing is what you use to create desk trinkets. In reality, we’re only beginning to see the potential of additive manufacturing. From printing food safe materials, to foods themselves the possibilities are just expansive. Take a look at what e-NABLE is doing with affordable prosthetic hands for kids. Read some of the stories about how doctors are leveraging 3D printing to accurately scan and recreate difficult procedures before picking up the scalpel. It’s still in its infancy and it’s already improving lives every day. Inspiring stuff!

Advice for aspiring model-makers

Much like any other art form, it’s only as good as the time you’re willing to put into it. Do your research and get familiar with the process you’ll be using to print. These printers all have unique challenges and advantages. If you design for your intended print process, you’ll fare much better than just hoping for the best. Shapeways has detailed material and process information for each of their products. Bookmark those pages and read them through before sending that final model to print!